Overview

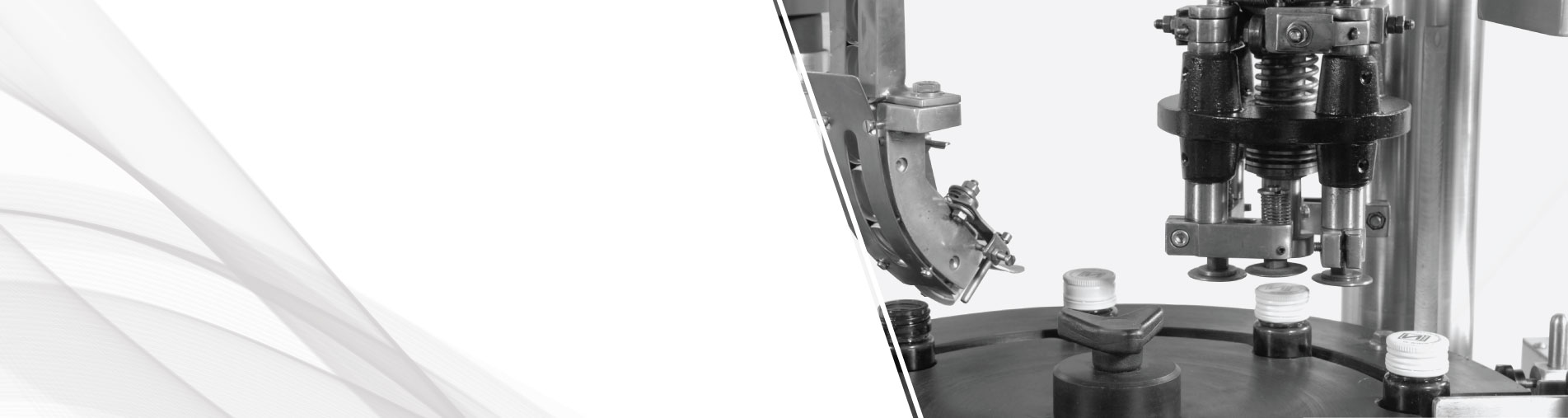

NPM's Automatic Single Head ROPP Cap Sealing Machine is a machine built on sturdy welded MS frame that closes completely in stainless steel where doors that facilitate the functions are provided.

While moving on the conveyor belt, the feed container is placed into the star wheel that brings the container under the sealing head as they move from left to right. As this process continues, the bottle is asserted with a cap from the delivery chute. The body and neck of the container are placed below the rotating head, where the sealing operation of threading and sealing takes place.

Specification

| Technical Specifications | ||

|---|---|---|

| Model | NARCS - 60 | |

| Output/Hour* | 1000 to 3000 bottles. | |

| Direction of Movement | Left to Right | |

| No. of Sealing Head | 1 Nos. | |

| Electrical Specification** | Main Motor | 1 HP / 415 Volts / 50 Hz. |

| Cap Feeding Bowl | 300 Watt, Magnetic coil | |

| Height of Conveyor** | 860 mm to 910 mm | |

| Change parts required | (A) Container: Star Wheel, Back Guide, Feed Worm | |

| (B) Cap Die, Delivery Chute, Bowl | ||

| Input Specifications | ||

|---|---|---|

| ROPP Cap | Diameter** | 19 mm to 38 mm*** |

| Specification | Height** | 15 to 18.3 mm |

| Container Size** | Round Shape | (A) ∅ 20 mm to ∅ 60 mm*** |

| (B) 58 mm to 120 mm*** (Height option for other bottle height available) | ||

| Flat / Square | (A) 30mm to 70 mm (Length)*** | |

| (B) 20 mm to 50 mm (Width)*** | ||

| (C) 58 mm X 120 mm*** (Height option for other bottle height available) | ||

| * Depends on bottle size, cap size and type of cap. | ||

| ** Can be customized. | ||

| *** With help of change parts. | ||

| Utility Requirement | ||

|---|---|---|

| Electrical supply | 3 Phase + Neutral + Earthing | |

| Electrical load | 0.75 KW | |

Salient Features

- No cap machine stop arrangement.

- No container No cap arrangement.

- SS elegantly matt finished body.

- Single motor synchronizes conveyor, star wheel, & platform turret.

- Adjustable height of conveyor belt, to align with other machine of the line.

- Sealing pressure can be varied to suit different gauges and size of caps.

- Low noise level, low power consumptions.

- SS cladding or hard chrome platting of all exposed parts to ensure long life and resistance against corrosion.

- Synchronized A/C drives to synchronize, Conveyor, Star wheel and Platform turret & capping bowl.

- Adjustable bottle height gauge for easy and quick setting.

Request a quote

NEWSLETTER

Get monthly updates about latest products, news and events from NPM Machinery.